Advanced Product Design, Spring 2016

Advanced Product Design focused on the processes and methods for designing products, including: need finding and need specification, ideation and concept selection, design thinking, user-centered design, human factors, sketching, gathering user feedback, rapid prototyping, intellectual property, and business planning to enable successful product launch.

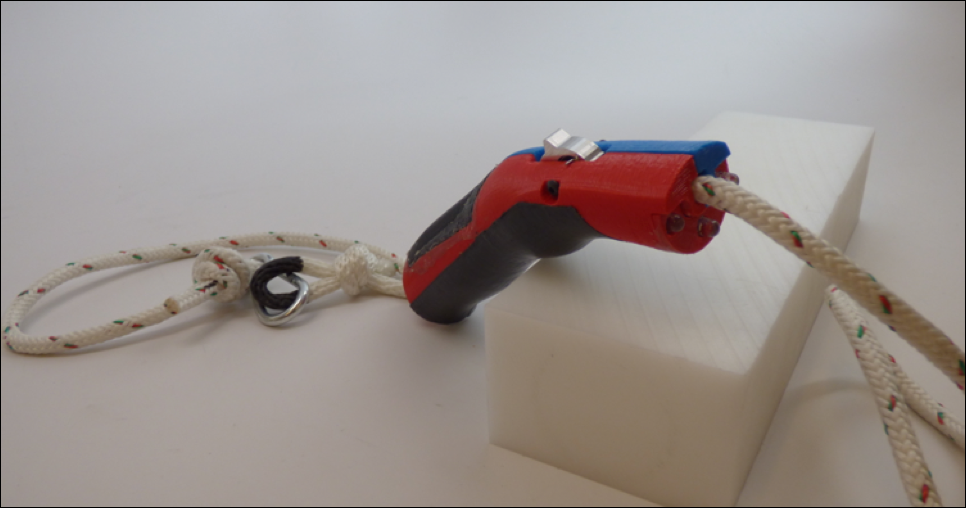

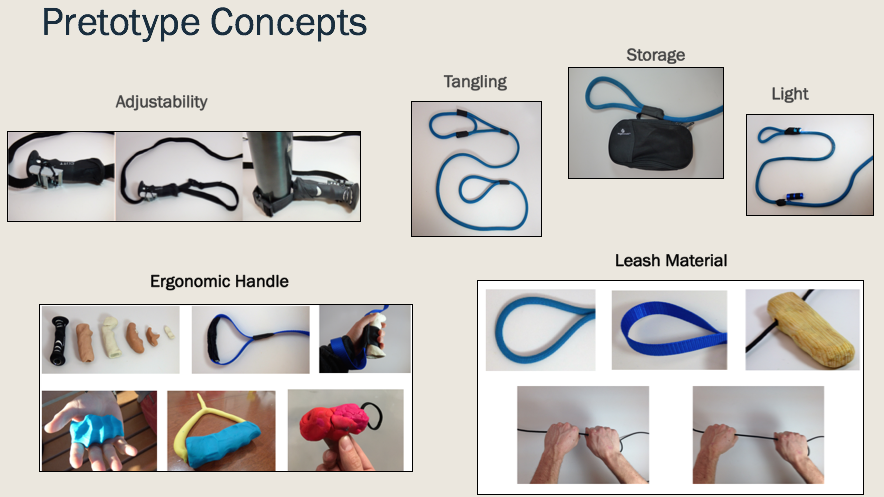

As lifelong pet owners, my team and I recognized several challenges facing consumers during dog walking. After interviewing dozens of dog owners around Colorado, we found that other pet owners dealt with similar challenges and products that did not meet their needs. Thus, we saw an opportunity to design a product that could improve the process for users. The goal of the product's design was to offer the user: improved safety and reliability, increased functionality and adjustability and more comfort for pets and owners.

After defining the problem and identifying our user's needs, we designed a diverse array of pretotypes and solicited the same users to test each design and provide feedback. After multiple iterations of prototyping, user feedback, testing and re-designing, we had created a novel product that our users were thrilled to employ during a walk with their dogs. Lastly, we drafted a business plan that detailed how we would potentially launch our product into the market. Our business plan documented: how to finance our venture, market analysis, defining intellectual property and an operating plan to achieve a successful launch. The final prototype and business plan were presented to a panel of design and product development experts from around Boulder, CO.

Design for Manufacturability, Spring 2016

Design for Manufacturability was the second course in my Design MS coursework. This course focused on Design for Manufacturing and Assembly (DFMA) techniques, which I continue to employ to minimize product cost through design and process improvements.

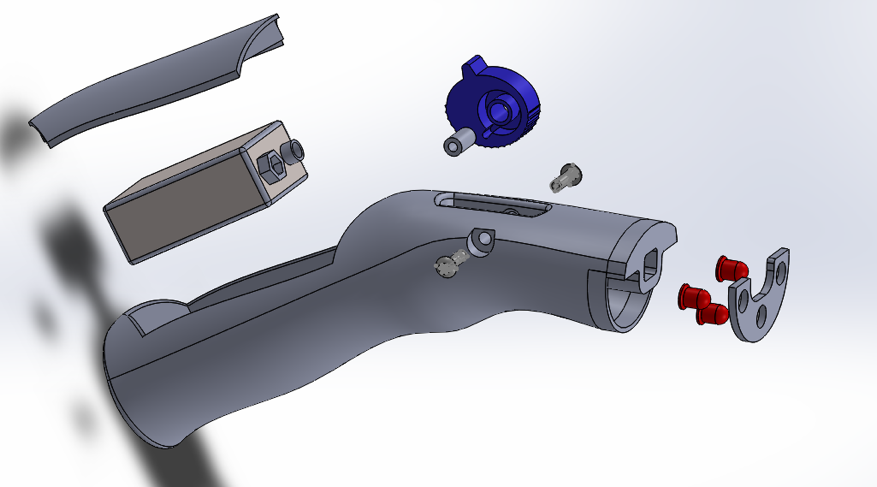

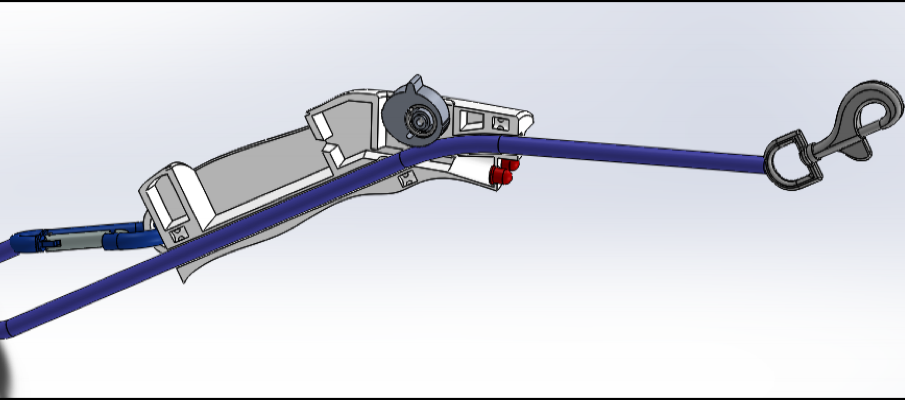

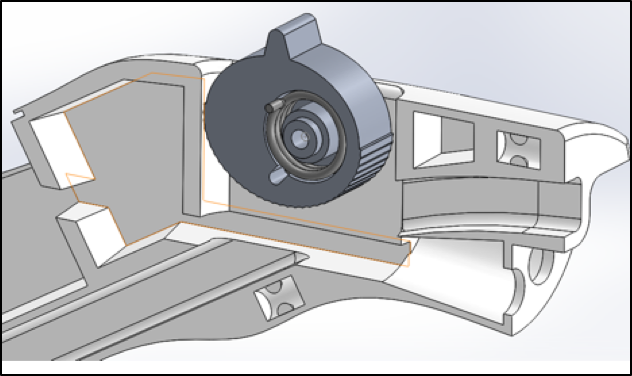

During this course, I worked on two major projects. The first was a reverse engineering project, where my team and I investigated an existing product and how to improve the product's design based on different DFMA metrics. The second project allowed my team to continue developing our leash prototype (from Advanced Product Design) by applying DFMA techniques to optimize the designs for functionality, assembly and cost. At the end of this process, we were able to transform our prototype concept into a product that was designed for production and ready to hit she shelves in a competitive market. After pitching the product, our team was awarded "Best Novel Design".

Soft Machines

The biological world and the engineered world differ in terms of mechanics: man-made machines are built from hard materials, while nature predominantly uses soft materials. In this course, I researched the emerging field of "Soft Machines" in order to apply the elegance of nature’s designs in engineering. The diverse applications of the soft machines studied included: soft robotics, tunable optics, artificial muscles and renewable energy.

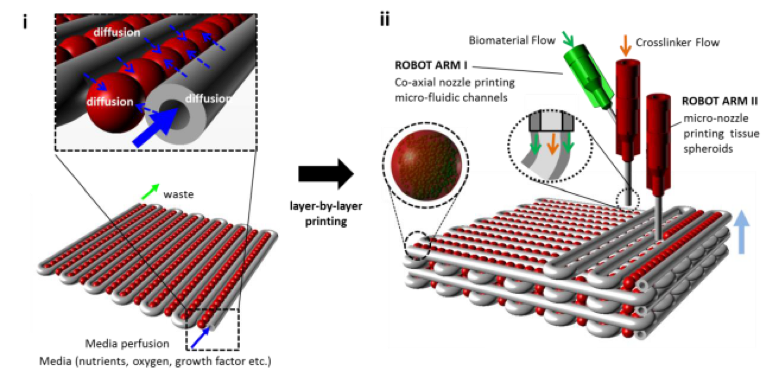

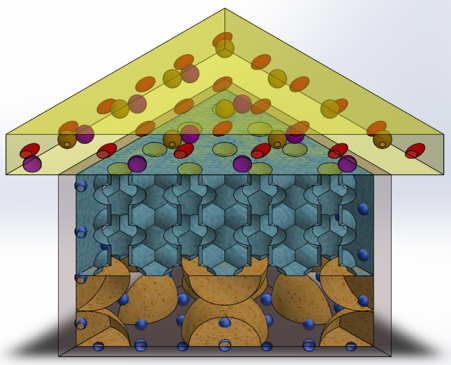

My primary coursework and research focused on the development of a soft, regenerative suture. The product aims to utilize bioprinting (3D printing human tissues) to minimize the shortcomings of traditional wound treatment for burn victims. The suture would offer a solution to protecting and regenerating native tissue that is also biologically equivalent to normal skin. Check out the link below to see our complete research proposal. My secondary research focused on the development of a "soft pump" that could be actuated and controlled without any rigid parts.